Continuing from the previous issue, this is another case study of EM use in Costa Rica, home to EARTH University, a base of operations for EM adoption in Central and South America.

At Ganadería Colono Real’s feedlot in Costa Rica, 2,000 to 2,200 head of cattle are raised, primarily Grey Brahman cattle.

For approximately six years (as of 2024), we have been utilizing EM technology to suppress odors and recycle manure resources. We are applying EM to achieve sustainable livestock farming by controlling odors to maintain a clean rearing environment while utilizing livestock manure as organic fertilizer.

However, this farm faced several challenges unique to livestock operations, including strong ammonia odors affecting animal nutrition and health, the proliferation of sanitation pests such as flies, and the proper management of manure.

Applying EM activated liquid while mixing

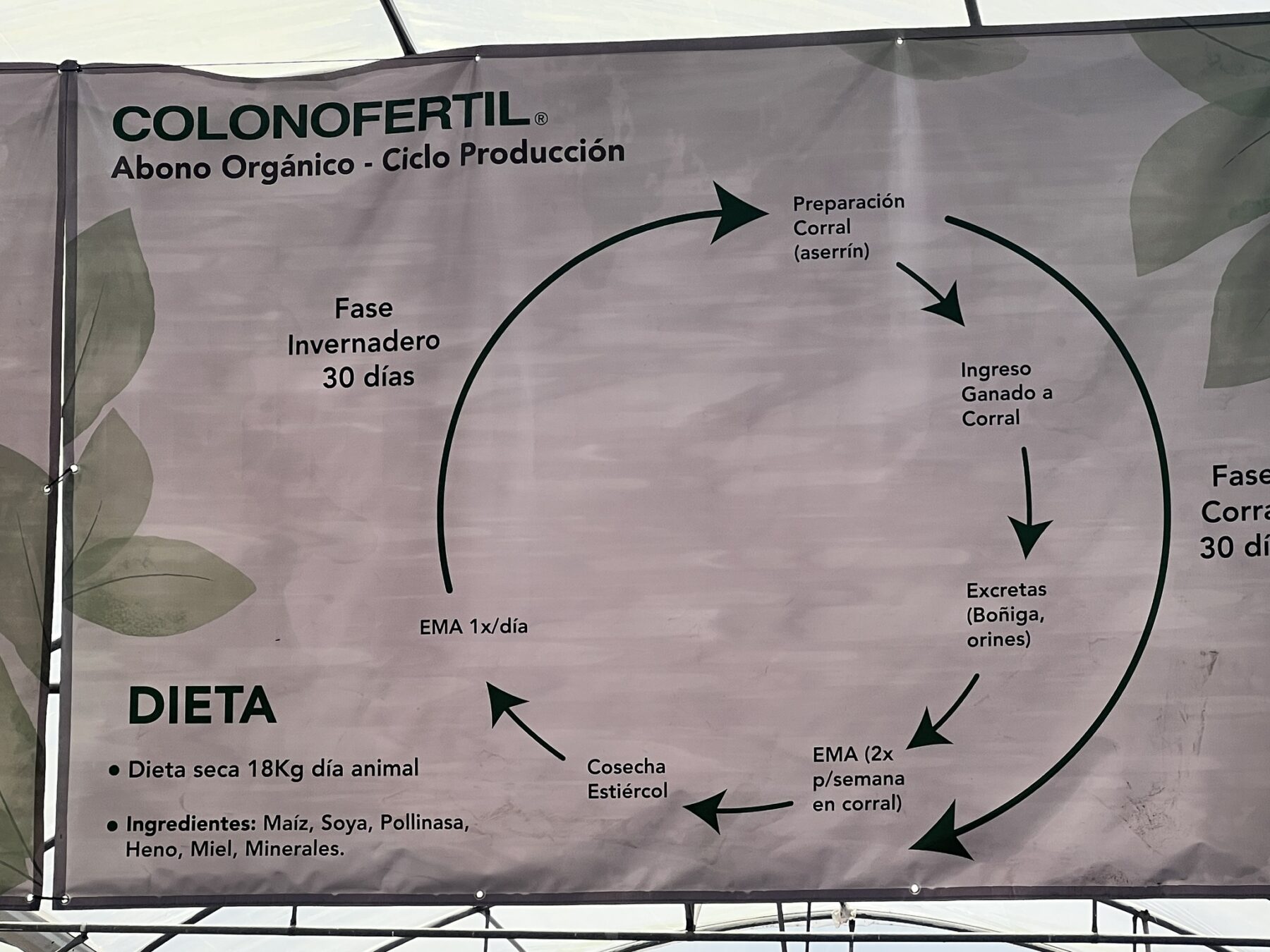

To address these challenges, the farm utilizes EM activated liquid to suppress odors and produce organic compost. The livestock area is divided into 64 sections. Every Monday and Thursday, approximately 18 liters of EM activated liquid is sprayed per section (about 300 square meters) to control ammonia odors.

Additionally, the approximately 120 tons of manure collected daily is composted at the composting facility. It is mixed with two truckloads of sawdust while spraying EM activated liquid, then piled up in the composting plant. EM activated liquid is used again during this process, and the pile is turned twice daily using specialized machinery. The EM activated liquid Solution is diluted to approximately 40% for use. Depending on weather conditions, it ferments into high-quality compost in roughly 30 to 35 days.

These initiatives have significantly reduced odors and pests like flies throughout the entire livestock facility. The compost production process, which previously took 2-3 months, has been drastically shortened to approximately 5 weeks, dramatically improving operational efficiency. Furthermore, the high-quality organic compost produced using EM has been certified as organic and has reached a stable weekly production level of about 400 tons. The facility has been transformed into a sustainable livestock operation that simultaneously addresses three key challenges: odor control, improved operational efficiency, and resource circulation.

(Source: “Sustainable Cycling Feedlot Operation” | EM GROUP JAPAN)

The composting cycle process

High-Quality Organic Fertilizer Utilizing EM

Read the original Japanese message at the link below.

2026.1.1 Updated.