A poultry production company in Paraguay started treating their waste water using EM. By treating waste water in an environment-friendly way, they could also reduce the cost!

POLLPAR S.A.is a renowned broiler production company in Paraguay that sells chicken under the brand name of “Kzero chicken”.

They not only sell to the domestic market but also export to more than 15 countries, producing more than 80,000 chickens per day.

Approximately 1,200 employees are working in different spots such as chicken farms, slaughter plants, animal feed industrial plants. The points of sales are distributed throughout the country, as well as at “La Cocina de KZero” (Kitchen of KZERO) in the capital city Asuncion.

POLLPAR’s chicken brand is certified ISO 9001 and HACCP quality standards.

Their mission includes providing high-quality products while considering the environment.

In doing so, they found EM Technology to treat their waste waster.

1. Odor generation at the Equalization and Reactor points.

2. Insufficient removal of organic load at final output.

3. Excessive production of sludge

1. To reduce odor generation at the Equalization and Reactor points.

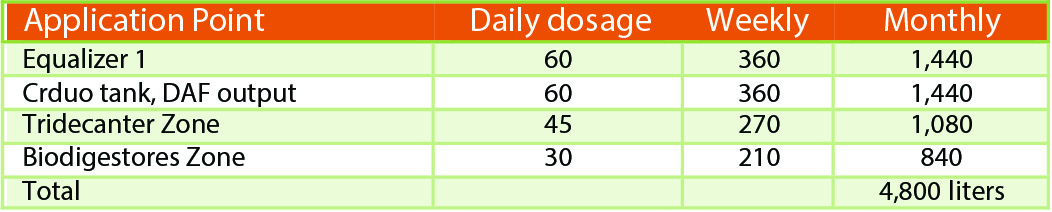

• Reactor: Application of AEM (Activated EM・1 ), diluted by 10%, with a spray system provided entirely by Tecnoempar S.A, EMRO’s partner in Paraguay.

• Primary Equalizer: Spray application of AEM, 100% without dilution, directly to the Equalizer.

2. To remove more organic load at final output.

• Phased Treatment

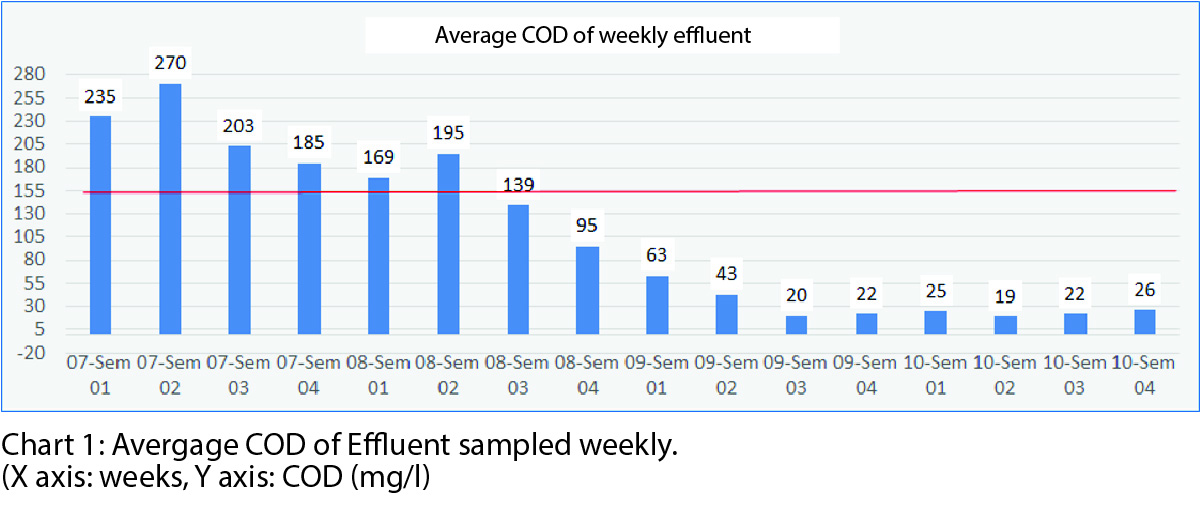

Phase 1 – Shock tretment for 3 months. AEM 300L/48hr was applied to reduce COD (Chemical Oxygen Demand, one of the indicaters of water quality), which was above the required quality standards because of the high mortality of the reactor bacteria.

Phase 2 – Stabilization treatment for 2 months. AEM 200L/48hr was applied for stable decomposition of organic load.

Phase 3: AEM 100L/48hr was applied for maintanance.

3. To reduce the production of sludge

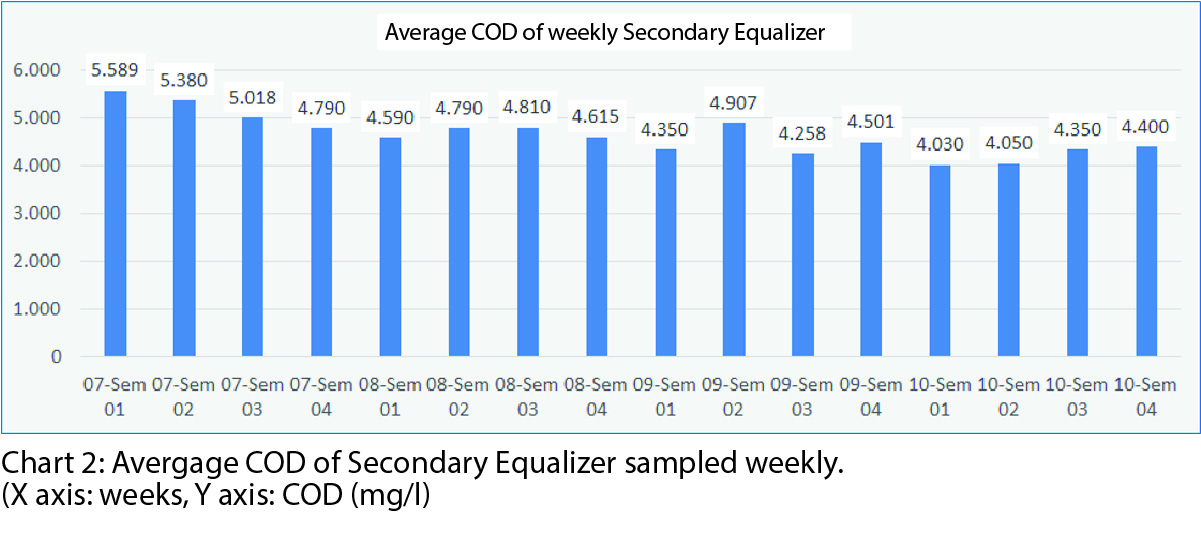

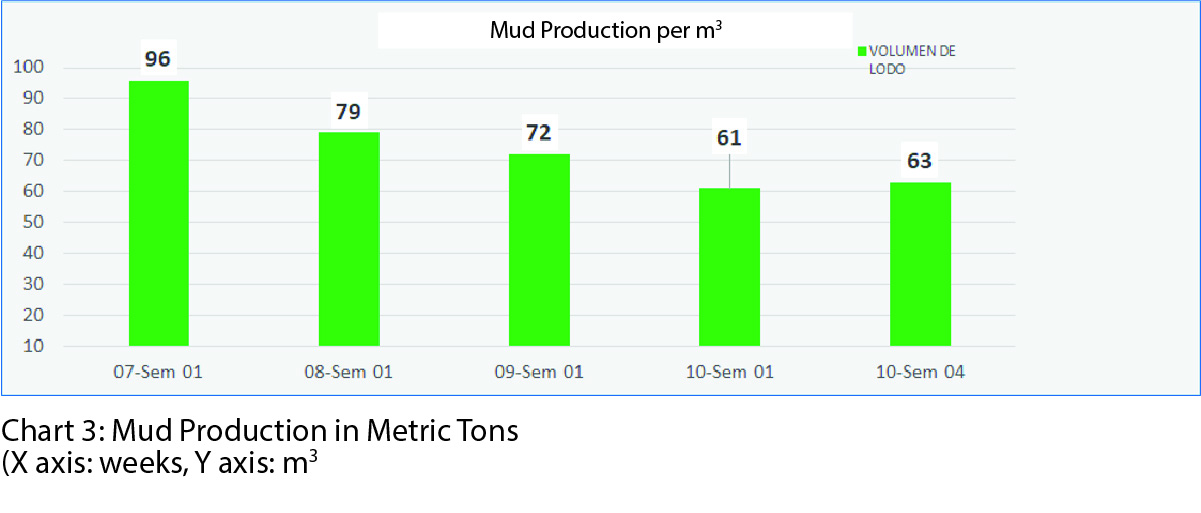

• AEM was applied to the Secondary Equalizer from the beginning of the process. It helped reduce the generation of mud in the system to 30% to 40% of what used be produced before EM application.

Aerobic Reactor and Sedimentator

Application in an Aerobic Reactor

Application in an Aerobic Reactor

They could see the reduction of organic load in the biodigestion process by applying AEM from the beginning of the treatment process, as well as pretreating the effluent upon receiving the effluent in the equalizer and in the biodigestion process itself inside the aerobic biological reactor.

A considerable reduction of sludge was also noticed.

It was reduced by 30 to 40%, consequently reducing the cost of the final disposal of the waste.

Most importantly, the effluent output quality was significantly improved. COD dropped from around 200 to 20-30.

For further information, please contact;

Ruta Transchaco Km. 46 1/2, Barrio Ecomipa Cerrito- Benjamin Aceval- Dto. de Presidente Hayes, Paraguay

TEL: +595-982-586230

E-mail: jlmartinez@em-la.com

E-mail: jorgeolm2@gmail.com

WEB: http://www.em-la.com/es/

facebook: https://www.facebook.com/EMPAR-100542690091388/

2021.3.19 Updated